Article

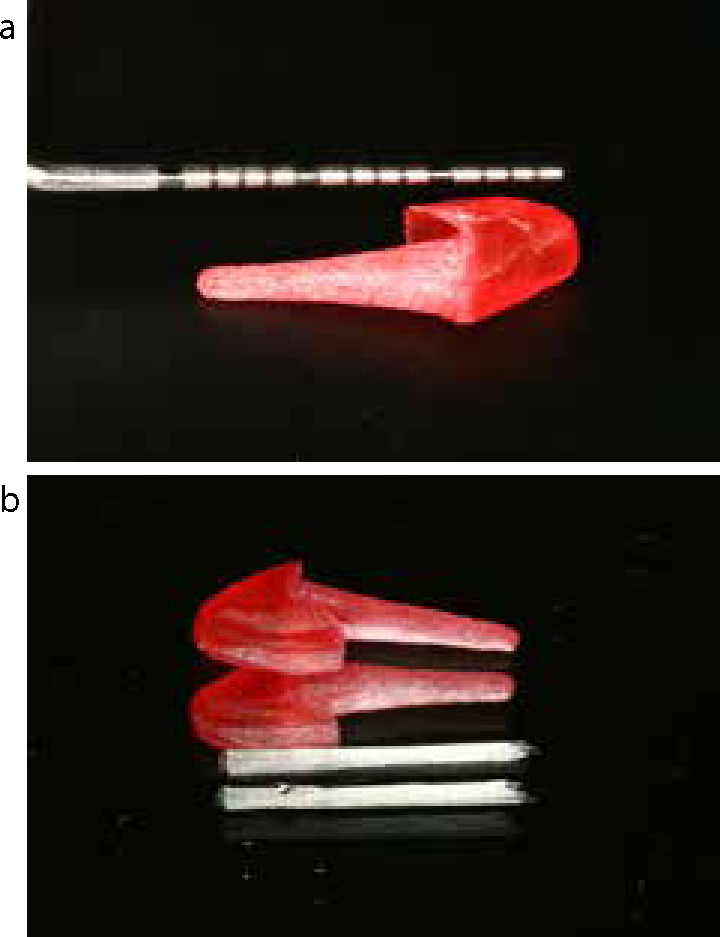

The introduction of carbon or glass fibre post systems may provide an alternative to metal posts for their biomimetic behaviour and favourable aesthetics when all-ceramic crowns are to be placed. However, prefabricated posts with direct cores made of glass ionomer or composite resin are less reliable than one-piece cast post and core, primarily because of delamination at the interface between the post and the core and compromised retention, especially in cases of wide, non-circular, or extremely tapered canals. A new indirect technique for the fabrication of a custom-fabricated post and core restoration made of laboratory composite resin material reinforced with fibres is presented.

Endodontically treated teeth often require post and core restorations for retention purposes because of extensive loss of tooth structure due to caries or fracture. The cast gold post and core has been considered the gold standard because of its excellent success rate, favourable long-term prognosis and good adaptation. Unfortunately, several disadvantages are associated with metal post and core restorations, such as root fractures and a compromised aesthetic result when placed under all-ceramic crowns.1,2

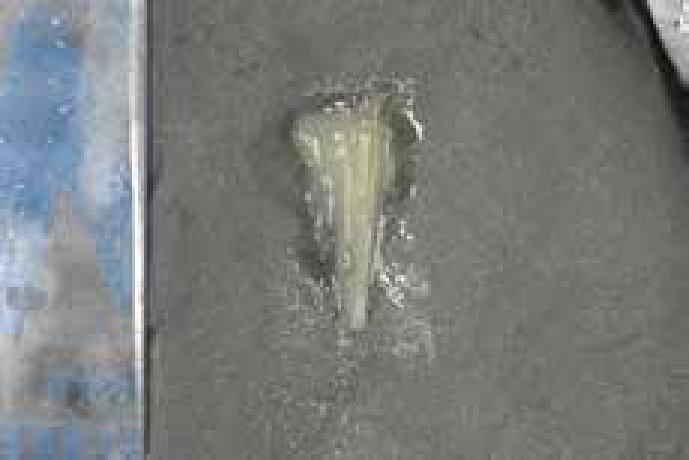

Carbon or glass fibre post systems may provide an alternative to cast or prefabricated metallic posts. These post systems have been developed with a modulus of elasticity values closer to that of human dentine, distributing the stresses more evenly along the root and causing fewer catastrophic failures.2,3,4 Moreover, post and core restorations made of glass or quartz fibre posts and composite resin build-ups allow improved aesthetics when all-ceramic crowns are to be placed. However, fibre post and core restorations have disadvantages and clinical problems. Delamination at the interface between the post and the core and compromised retention in cases of wide, non-circular, or extremely tapered canals, where cylindrical prefabricated posts may not achieve adequate adaptation to the canal, have been reported.5 Post adaptation to the canal walls represents an important element in the biomechanical performance of the prosthetic restoration. Dislocation of the posts and compromised fracture resistance of the teeth due to interfacial gaps between the post and the intracanal dentine have been reported.6,7

Teeth with wide or flared canals are more susceptible to fracture due to the weakened thin remaining walls. A variety of direct clinical techniques have been introduced as alternative options to restore structurally compromised endodontically treated teeth damaged by caries, trauma or congenital disorders. Experimental dentine posts8,9 or reshaped fibre posts10 to adapt to the walls of non-circular root canals have been proposed. Prefabricated posts associated with resin reinforcement of the root dentine walls or individually shaped polyethylene woven fibre ribbon reinforced post and core systems have been advocated.11,12,13 Increased fracture resistance10,14,15 and decreased microleakage16 have been reported when adapted fibre-reinforced custom fabricated dowel systems were used to restore endodontically treated teeth with wide flared canals. It is questionable whether wall adaptation or complete light polymerization of the composite resin material can be achieved at the apical portions. Limited moisture control and geometry factors (c-factor) have been correlated with inferior bonding effectiveness to radicular dentine.14,17,18

This article describes an indirect technique for the fabrication of a one piece custom-fabricated post and core restoration made of laboratory light-cured composite resin material and reinforced with fibres.

Procedure

Discussion

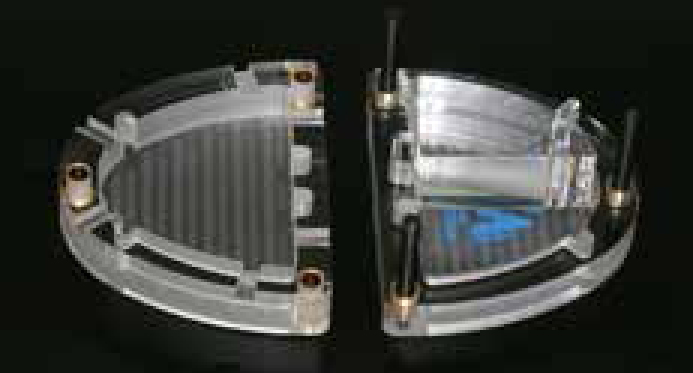

The one-piece fibre/polymer post and core restoration is proposed as an alternative to cast post and cores when core shade is relevant for the definite restoration, and in cases of a substantial amount of coronal tooth structure loss, along with wide, elliptical or highly tapered canals. Possible immediate benefits of this post system include minimal tooth structure removal during canal reshaping, conformation to canal shape and greater post-to-canal adaptation. Surrounding cement thickness and accompanying polymerization shrinkage are diminished and an increased possibility of chemical interaction and chemical bond with the resin cement may be offered. A favourable foundation for eliminating discoloration caused by a metallic post placed under an all-ceramic crown can be achieved. With the proposed indirect laboratory technique, steps can be better controlled and a higher degree of material polymerization can be accomplished. The use of the transparent flasks along with the transparent impression material allows for primary polymerization, while secondary polymerization in a post-curing device may increase the conversion rate of C=C double bonds with sequence improvement in the physicomechanical properties of the material.19,20 Even though it is a laboratory technique, minimal equipment is required, allowing tooth preparation, fabrication and cementation of the post and core restoration to be completed in the dental practice within a single appointment. Limitations of the technique include the excess of the composite material, which may cause seating difficulties, the additional time needed and lack of scientific data to support it.